KDE700XF-535-G3

Overview

Product is NOT STOCKED at fulfilment center. Minimum order quantity of 50 required. 8+ week lead time. Contact sales for details.

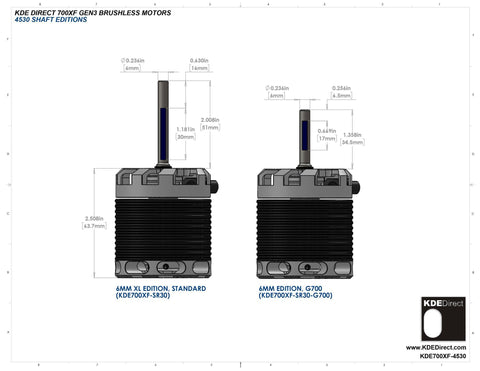

NOTE: Use the pull-down menu above to select the shaft of your choice:

- 6mm XL Edition, Standard (KDE700XF-SR30)

- ф6mm shaft diameter, 51mm shaft extension, 111.7mm overall length

- 6mm Edition, G700 (KDE700XF-SR30-G700)

- ф6mm shaft diameter, 34.5mm shaft extension, 98.2mm overall length

Replacement Bearings: KDE700XF-BRK

The new KDE Direct 700XF-535-G3 High-Performance Brushless Motor is an extremely efficient and powerful motor for any 650 through 750-class single-rotor helicopter or fixed-wing application. Using the latest Computer-Aided Magnetic Field Analysis software to design the most efficient and optimized design for high-level, performance-driven flight applications and the highest-quality materials and processes in manufacturing; the new "G3" series is the new generation in performance for the single-rotor and UAS marketplace. The motors are designed with performance and durability in-mind, with features unseen in the current market: (1) high-grade, 240°C continuous (340°C maximum) high-temperature solid-core copper windings for failure-free operation in extreme-climates, (2) Japanese-built, 0.2 mm silicon-steel stator laminations and Kevlar tie-wraps for high-efficiency performance, and (3) quad-bearing supported, ABEC-7 bearings for maintenance-free and worry-free flying for hundreds of hours. These are just a few of the advantages built-in to these motors, and every detail of the motors was scrutinized to produce the absolute best available; for a wide-range of flight applications.

Motors include 200°C, 10 AWG silicone-wire leads and ф6.5mm 24K Bullet Connectors (KDEXF-BC65, pre-soldered to the motor leads and ESC matching Bullet Connectors).

Specifications

Material: Neodymium N40UH

Models: High-voltage, 650- through 750-class single-rotor and UAS applications (compatible with M4 x ф30mm and M3 x ф25mm mounting profiles) and ф6mm exit shaft.

Finish:

- Clear anodize, mirror-polish CNC gloss endbells

- Black electro-plate, CNC gloss central core (flux ring)

Full Specifications:

| Kv (Motor Velocity Constant) | 535 RPM/V |

| Kt (Motor Torque Constant) | 0.0178 Nm/A |

| Km (Motor Constant) | 0.1881 Nm/√(W) |

| Maximum Peak Current | 250 A (2 s) |

| Maximum Peak Power | 11,100 W (2 s) |

| Maximum Continuous Current* | 126 A (180 s) |

| Maximum Continuous Power* | 5,595 W (180 s) |

| Voltage Range | 29.6 V (8S LiPo) - 60.9 V (14S LiHV) |

| Io (@10V) | 2.4 A |

| Rm (Wind Resistance) | 0.009 Ω |

| Magnetic Poles | 10 (12S10P) |

| Bearings | Quad, 698ZZ/MR148ZZ |

| Mount Pattern | M4 x ф30 mm, M3 x ф25 mm |

| Stator Class | 4530, 5T+5T, YY |

| Stator Windings | 14-Strand, ф0.38 mm |

| Shaft Diameter | ф6 mm (ф8 mm Internal) |

| Shaft Length | 51 mm |

| Motor Dimension | ф56 mm x 63.7 mm |

| Motor Weight | 520 g (560 g with Wire Leads) |

| Motor Leads | 10 AWG, 200°C |

| Cooling System | High-Volume Centrifugal Fan |

| Motor Timing | 5° - 15° |

| ESC PWM Rate | 8 - 32 kHz |

*: Brushless motor requires consistent open airflow (5 mph or greater) across the windings to maintain maximum continuous current and power ratings during operation. Performance figures are provided as guidelines for normal conditions and operation; environmental factors, such as air temperature and humidity, can significantly alter the maximum performance limits of the motor.

Manuals

- KDE700XF-535-G3 Design Geometry Dimensions Specification Sheet (PDF)

- KDE700XF (4530 Stator) Brushless Motor Series Shaft Editions (PDF)

- XF Generation 3 Brushless Motor Series Gearing Recommendations (PDF)

- XF Generation 3 Brushless Motor Series Technology Review (PDF)

- KDE Direct Design Engineering - Episode IX: XF Gen3 Brushless Motors (YouTube)

- Performance Flight Video (YouTube)

We Also Recommend