Brushless Motors for Robotics | Common Questions Answered

As of 2018, KDE Direct has expanded into several new industries, including robotic applications. Since the launch, we’ve received a few questions regarding brushless motors for a wide variety of robotic applications, from BattleBots to microrobotic systems. Here is our roundup of common robotic questions along with our answers so you can get to building.

What Counts as a Robot?

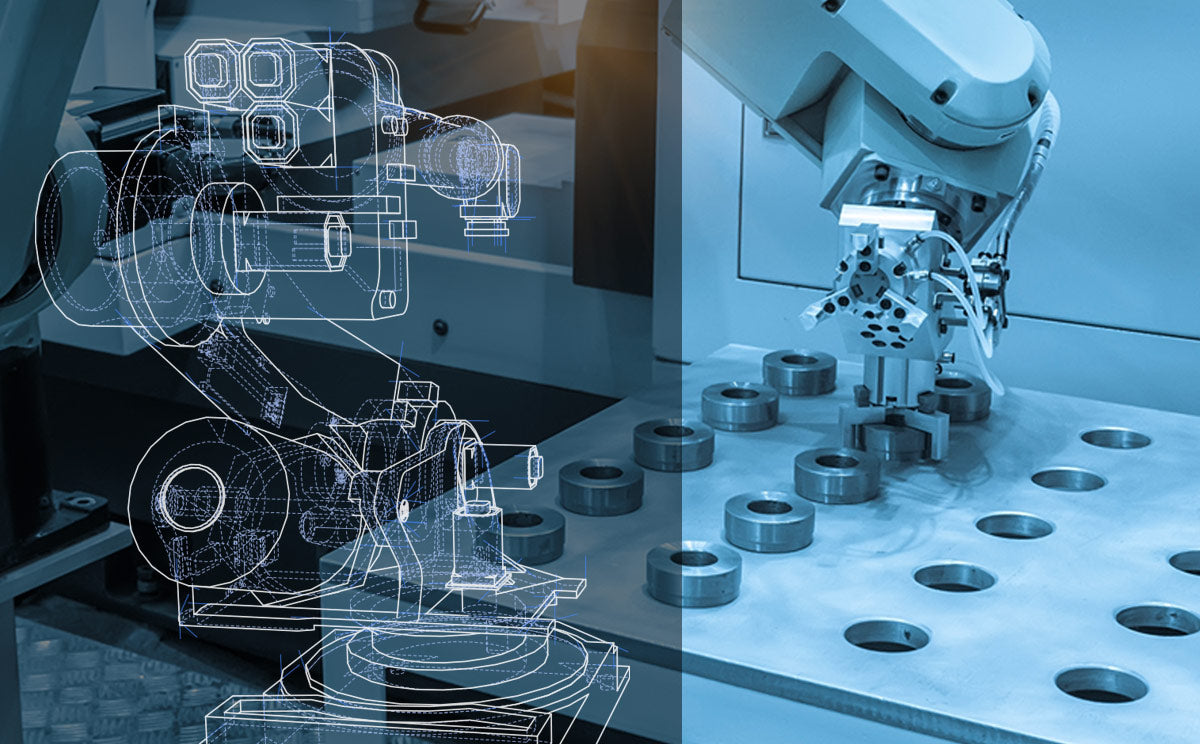

The definition of the word “robot” isn’t as broad as you’d expect. A robot is a man-made mechanical device that can move by itself, whose motion must be modeled, planned, sensed, actuated and controlled, and whose behavior can be influenced by programming. This leaves only a bit of wiggle room, implying that a device can only be called a robot if it contains a movable mechanism that is influenced by sensing, planning, actuation, and control components. Motors and actuators are the devices which make the robot moveable by converting electrical energy into physical motion.

How Do Brushless Motors Work?

A brushless DC (BLDC) motor doesn’t directly operate from a DC voltage source. However, the basic principle of operation is similar to that of a DC motor. A BLDC has a rotor with permanent magnets as well as a stator with windings. This helps ensure that there are no sparks, which is one of the biggest advantages of the BLDC motor. The construction of a brushless DC motor is similar enough to the AC motor to be a true synchronous motor—with a few added perks.

The brushes in a DC motor come with several limitations: brush residue, brush life, maximum speed, and electrical noise. By removing the brushes, BLDC motors are cleaner, faster, more efficient, less noisy and more reliable.

Why is Eliminating Brushes So Important?

Mechanical brushes are often the weakest link in a motor. In applications like robotics, motors need to be light, efficient, and long-lasting. The elimination of these brushes has a number of benefits:

- Brush housing assemblies are mechanically complex, making them prone to fail from large shock loads.

- Spring-loaded brushes can bounce in large impacts, which can cause arcing.

- Brushes arc when transitioning between commutator bars, limiting their operating speed.

- Brushes are typically made from soft carbon alloys, so they wear out quickly and need to be replaced frequently.

- Additional electrical resistance from carbon brushes along with friction for sliding contact increases heat, which lowers motor efficiency.

Why Choose Brushless over Brushed?

The advantages of the brushless DC motor over its brushed counterpart include greater efficiency, higher reliability, lower electrical noise, better speed control, and, more importantly, no brushes or commutator to wear out. One of the biggest benefits of eliminating brushes is that it allows the motor to handle more peak current and spin much faster. This not only results in a higher speed but also ensures that you won’t need to replace your motors often; even if they’re used for rugged applications like BattleBots and rovers.

A brushless motor can do the same job as a brushed motor with a longer lifespan and only half the weight. In combat robots with a fixed weight budget, this size reduction also leverages additional weight savings since less armor is required to protect the motor. Brushless motors help engineers get the most power at the lightest weight.

The brushless motor’s decreased risk of sparking and their speed makes them ideal for today’s technology, helping both scientists and hobbyists build better machines for the future. Brushless motors today are used for rovers, prosthetic limbs, service robots, and even BattleBots.

What are Popular Applications for Brushless Motors in Robotics?

- Humanoid robots

- Space robots

- Multicopters

- Drones

- Radio control vehicles

- Industrial servos

- Hybrid vehicles

- High-end gearmotors

- Inspection robots

- Service robots

- Microrobotic systems

- Teleoperation robots

- Educational robots

- Household robots

KDE Direct Brushless Motors for Robotics

KDE Direct’s brushless motors for robotic applications provide market-leading performance for thousands of hours of maintenance-free usage. We’ve implemented ISO 9001 certification for all of our production facilities around the world. All of our products are CE (European Conformity), RoHS (The Restriction of Hazardous Substances), and WEEE (The Waste Electrical and Electronic Equipment Directive) compliant for both commercial and industrial applications.

Share this post

- Tags: brushless motors, brushless motors for robotics, drones, how brushless motors work, robotics, robots