KDE2814XF-515

Overview

Recommended ESC: KDE Direct UAS 35A+ Multi-Rotor Series

Alternate ESC: KDE Direct UAS 20A+ LV Multi-Rotor Series

Recommended Propeller: KDE Direct 12.5" x 4.3 Triple-Propeller Blades

Includes:

-

One (1) KDE Direct XF UAS M6 x 15mm Propeller Adapter Assembly (KDEXF-PA615-LH)

- One (1) KDE Direct XF UAS Motor Adapter Plate Assembly (28XX Edition)

- One (1) KDE Direct XF UAS Propeller Bracket Assembly (Clear Edition)

- One (1) KDE Direct XF UAS Propeller Bracket Adapter (ф4.0 x ф6.0 x 2.5mm)

- Three (3) KDE Direct XF ф3.5mm 24K Bullet Connectors (KDEXF-BC35, Female)

- Four (4) M3 x 0.5 x 6 mm Flat Head Phillips Head Machine Screws (Class 12.9)

- Five (5) M3 x 0.5 x 8 mm Socket Head Cap Screws (Class 12.9)

Replacement Parts:

The new KDE Direct 2814XF-515 Multi-Rotor Brushless Motor is an extremely efficient and powerful motor for numerous multi-rotor and sUAS applications, and was designed to bring high-quality and vibration-free motors to the market. The motors are designed with performance and durability in-mind, with features unseen in the current market: (1) high-grade, 200°C continuous high-temperature solid-core copper windings for failure-free operation in extreme-climates, (2) Japanese-built, 0.2 mm silicon-steel stator laminations and Kevlar tie-wraps for high-efficiency performance, and (3) triple-bearing supported, ABEC-7 bearings for maintenance-free and worry-free flying for hundreds of hours. These are just a few of the advantages built-in to these motors, and every detail of the motors was scrutinized to produce the absolute best available; for a wide-range of flight applications.

Motor includes 200°C, 17 AWG, 635mm silicone-wire leads and ф3.5mm 24K Bullet Connectors (KDEXF-BC35, pre-soldered to the motor leads and ESC matching Bullet Connectors).

UAS Multi-Rotor Brushless Motor Series Technology Review (PDF)

Specifications

Material: Neodymium N45UH

Models: Universal mounting pattern provides simple installation for a wide-range of multi-rotor and sUAS applications: M3 x ф25mm, M3 x ф19mm, M2.5 x ф19mm.

Finish:

- Clear anodize, mirror-polish CNC gloss endbells

- Black electro-plate, CNC gloss central core (flux ring)

Compatible With:

- Replacement Shaft: KDE2814XF-SR

- Replacement Bearings: KDE28XF-BRK

- Propeller Adapter (Right-hand): KDEXF-PA615-RH

- Propeller Adapter (Left-hand): KDEXF-PA615-LH

Full Specifications:

| Kv (Motor Velocity Constant) | 515 RPM/V |

| Kt (Motor Torque Constant) | 0.0185 Nm/A |

| Km (Motor Constant) | 0.0514 Nm/√(W) |

| Maximum Continuous Current* | 24 A (180 s) |

| Maximum Continuous Power* | 535 W (180 s) |

| Voltage Range | 14.8 V (4S LiPo) - 26.1 V (6S LiHV) |

| Io (@10V) | 0.3 A |

| Rm (Phase to Phase Resistance Delta Wound) | 0.130 Ω |

| Stator Poles | 12 (12S14P) |

| Magnetic Poles | 14 (12S14P) |

| Bearings | Triple, 684ZZ, 624ZZ |

| Mount Pattern | M3 x ф25 mm, M3/2.5 x ф19 mm |

| Stator Class | 2814, 0.2 mm Japanese |

| Shaft Diameter | ф4 mm (ф4 mm Internal) |

| Shaft Length | 5.5 mm |

| Motor Diameter | ф35.5 mm |

| Motor Rotor Inertia | 0.093 kg*cm^2 |

| Motor Length | 31.7 mm |

| Motor Weight | 95 g (125 g with Wires/Bullets) |

| Propeller Blade Size | Up to 15.5"-DP (12.5"-TP Maximum on 6S) |

| Motor Advance Timing | 22° - 30° |

| Motor Drive Frequency | 16 - 32 kHz |

| Wire Gauge | 17 AWG |

| Enameled Magnet Wire Thermal Class | 200 °C |

*: Brushless motor requires consistent open airflow (5 mph or greater) across the windings to maintain maximum continuous current and power ratings during operation. Performance figures are provided as guidelines for normal conditions and operation; environmental factors, such as air temperature and humidity, can significantly alter the maximum performance limits of the motor.

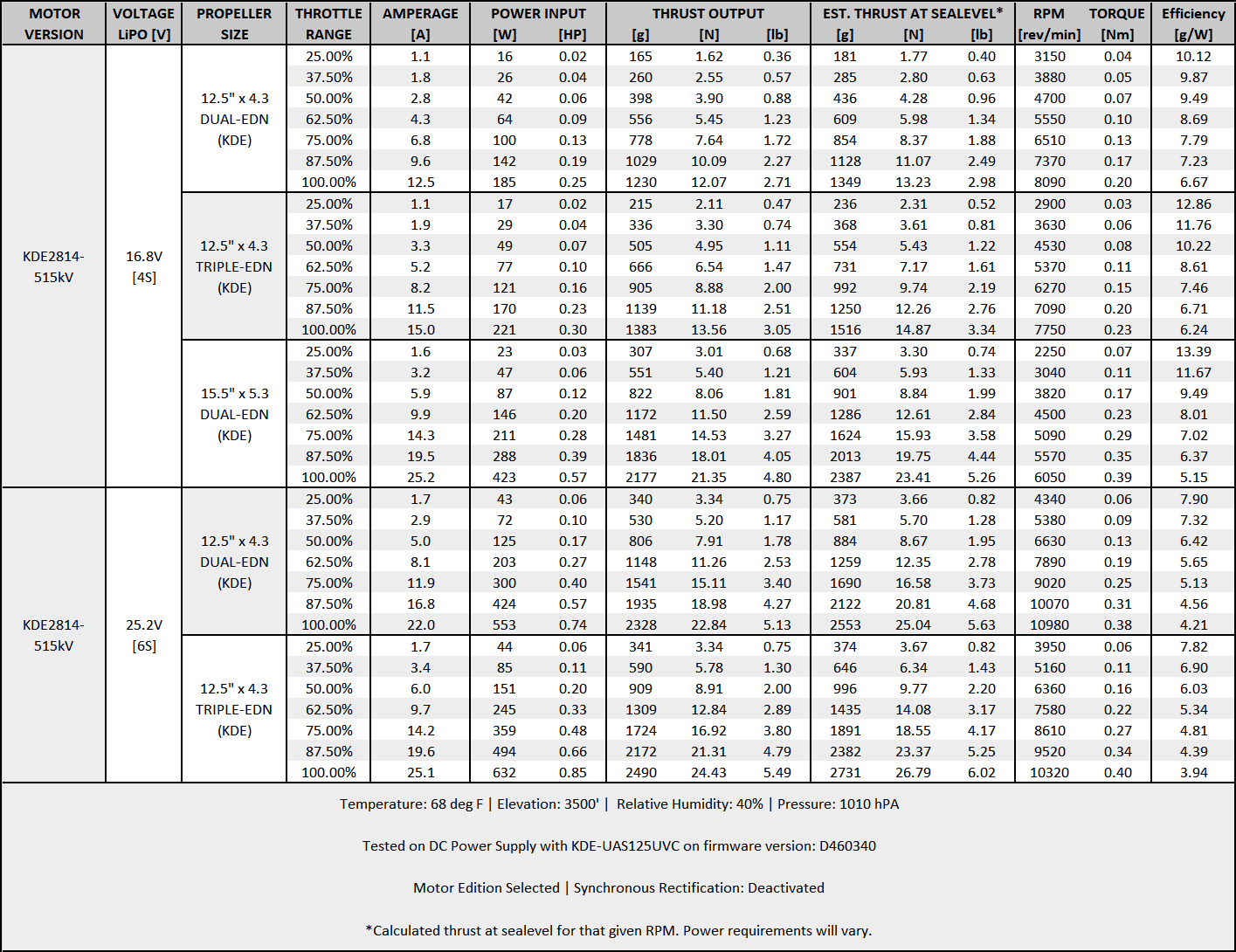

Performance Data

Manuals & Models

Manuals

- KDE2814XF-515 Design Geometry Dimensions Specification Sheet (PDF)

- KDE2814XF-515 Universal Mounting Pattern Specification Sheet (PDF)

- KDE2814XF-515 Components and Hardware Specification Sheet (PDF)

- KDE2814XF-515 Motor Adapter Plate Specification Sheet (PDF)

- KDE Direct Design Engineering - Episode VIII: XF M-R Brushless Motors (YouTube)

Models

To decompress the files, any reputable unarchiver will work such as WinRAR, 7-Zip, PeaZip, etc.

We Also Recommend